Maltose 70kg

The flavor is mild and layered, and the Maillard response is better

Strong water retention and anti-aging ability, extending the shelf life of products

It has excellent thermal stability and fermentation properties, and is suitable for multiple processes

Anti-crystallization and anti-sand return, optimizing product texture

Natural attributes adapt to health needs

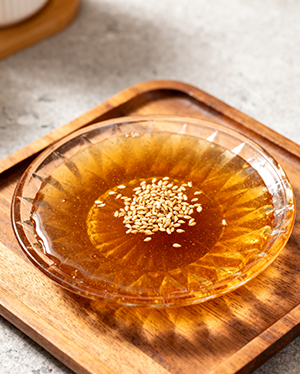

Product Introduction

Maltose is a natural sugar made from starch (rice, corn and other grains) catalyzed by amylase saccharification in malt, which has been used in China for more than 2,000 years, and is known as "candy" in ancient times. According to the production process and maltose content, it can be divided into three categories:

Ordinary maltose: maltose content is about 40%~50%, light yellow viscous liquid, with a faint malt aroma;

High maltose syrup: maltose content 50%~70%, higher transparency, purer sweetness, is the mainstream choice of the food industry;

Ultra-high maltose syrup: maltose content ≥70%, solids content up to 85%, high viscosity, suitable for high-end processing needs.

Modern industrial production follows the process of "starch liquefaction→ enzymatic hydrolysis saccharification→ decolorization and filtration→ concentration and refining", and high-quality products need to meet strict indicators: solids 70%~85%, sugar boiling temperature ≥ 145°C (excellent ≥ 155°C), DE value >42%, and the content of heavy metals lead arsenic is less than 1ppm, the total number of bacteria ≤ 1000 cfu/g. The traditional process is naturally fermented with rice and malt, and then boiled and concentrated over slow heat, which is time-consuming but more flavorful, such as the maltose making skills in Wuzhou, Guangxi, which have been selected as intangible cultural heritage.

Application of the product

1. Bakery: core functional raw materials

As a "new alternative to sucrose" in the baking industry, maltose assumes multiple roles such as sweetness, moisturizing, coloring in various pastries

Bread and toast: Replacing 100g of granulated sugar with 125g of malt syrup (while reducing 25g of formula liquid) can extend the fermentation time by 30%, increase the elasticity of the finished product by 20%, and extend the shelf life from 3 days to 5 days, especially suitable for the taste optimization of low-sugar meal replacement bread.

Mooncakes and Chinese pastries: 10%~15% is added to the lotus paste and bean paste fillings, which can lock the moisture of the filling, so that the crust and the filling are not separated, the dry cracking rate of Cantonese mooncakes is reduced from 18% to 2% after application; When making sachima, it can replace part of the honey to improve adhesion and reduce the sweetness;

Biscuits and crisps: Adding 5%~8% to the cookie recipe can make the biscuit layers clearer and increase the crispiness by 30%; The surface of the almond shortbread is sprinkled with maltose powder, which forms a burnt puff pastry after baking, the flavor is more intense;

Fillings and sauces: Adding 5% to bake-resistant jam can resist baking at 180°C to avoid collapse and flow, and the "filling rate" of a bakery has been reduced from 20% to 3% after application.

2. Meat products and marinated dishes: the key to coloring and locking the juice

In the processing of roasted meat marinated meat, maltose is the core raw material of "crispy skin coloring":

Before roasting char siu and roast duck, use maltose and water to mix 1:3 to make sugar water brush and coat the skin, forming a tight and crispy skin at high temperature, and locking in the juice, so that the moisture content of the finished product increases by 8%, and the taste is more tender;

Adding 3%~5% to braised meat products can improve the brightness of color, make braised eggs and braised tofu appear natural amber, and enhance the elasticity of ingredients to avoid being soft and rotten after cooking.

3. Candy and Snack Food: Texture Optimization Core

Suitable for various categories such as gummies, hard candies, and coated foods

In the production of gummies, high maltose syrup is used as the main material (accounting for 30%~40%), which can make the finished product Q-elastic and translucent, and the anti-sand return rate reaches more than 95%;

Sugar gourds and sugar-fried chestnuts are used when hanging pulp on the surface, which can form a crystal clear sugar shell, and is not easy to melt and absorb moisture, and the shelf life is extended to 2 days;

In the wrapped nut, maltose and sugar solution are mixed 1:3 to form a coating, which can make the seasoning powder adhere evenly, and the moisture absorption rate is reduced by 30% compared with maltodextrin.

4. Beverage and Brewing: Fermentation and flavor conditioning

The addition of high maltose syrup (accounting for 10%~15% of raw materials) in beer brewing can improve the mellowness of the wine, shorten the fermentation cycle, and reduce the production cost by 12%;

As a sweetener in functional beverages, it replaces 20% sucrose to improve taste levels while reducing the risk of blood sugar fluctuations.

Packaging & Shipping

We usually use bulk cargo, tank trucks, container transportation. We will arrange the most costeffective shipping method according to the quantity of products. All products will be reinspected before shipping. We guarantee that all products are strictly inspected in good condition before shipment, we strive for 100% customer satisfaction in every sale completed. The packaging is standard export packing, or customized packaging according to your requirements, professional cargo transportation agent.

Sales Service

Pre-sales Service

Provide application solution support to customers prior to purchase, helping them gain a clear understanding of both the products their practical applications.

Offer detailed product consultation: Address customers' inquiries comprehensively, covering aspects such as product functions, features, pricing, usage methods.

Conduct demand analysis: Recommend tailored product solutions based on the customer's specific industry, application scenarios, and pain points.

Supply necessary information: Provide materials like product manuals, case studies, and quotations to facilitate customers' decision-making process.

In-sales Service

Deliver convenience and support to customers during the transaction phase to ensure the process proceeds smoothly.

Process orders efficiently: Input order information quickly and accurately, and confirm key details including product specifications, quantities, and delivery dates.

Offer payment guidance: Assist customers in completing the payment process and answer questions related to payment methods and invoice issuance.

Maintain progress communication: Provide timely updates to customers on order processing status and logistics information, keeping them informed and reassured.

After-sales Service

Provide continuous support to customers after the transaction is finalized, with the goal of enhancing customer satisfaction and fostering long-term loyalty.

Handle returns and exchanges: Process return and exchange procedures for customers in accordance with established regulations, alleviating their concerns.

Conduct customer follow-ups: Gain insights into customers' product usage experiences, collect feedback, and use this information as a basis for product improvement and service optimization.

Company Introduction

Founded in 1997, Bowlingbao Biotechnology Co., Ltd. has always focused on modern bioengineering technologies such as enzyme engineering and fermentation engineering, engaged in the research and development, manufacturing and program services of functional sugars, is a national key high-tech enterprise led by bioengineering, a national key leading enterprise in agricultural industrialization, a national manufacturing single champion enterprise, a national high-tech zone, and a national high-tech biological industry base core and backbone enterprise. In 2009, the company was listed on the Shenzhen Stock Exchange, becoming the first A-share listed company in China with the stock code: 002286.

The pioneer and leader of China's functional sugar industry, adheres to the restoration of traditional medical and nursing wisdom with modern biotechnology, serves the big health industry, and has the ability to manufacture and serve all categories of functional sugar. A leading global provider of functional health solutions.

Product Catalog

Starch sugar: solid corn syrup, waxy corn starch, maltodextrin, malto-oligosaccharides, fructose syrup, maltose

Dietary fiber: polydextrose, resistant dextrin, water-soluble corn fiber

Prebiotics: isomalto-oligosaccharides, fructooligosaccharides, galacto-oligosaccharides, breast milk oligosaccharides, isomerized lactose

Sugar alcohols new sugar sources: allulose, erythritol, crystalline fructose, compound sweeteners, trehalose

Modified starch: special for yogurt, special for sauce, special for baking fillings, special special for baked products, special special for flour products, special special for meat products

Functional lipids: DHA algae powder, DHA algae oil, DHA algae oil crude oil