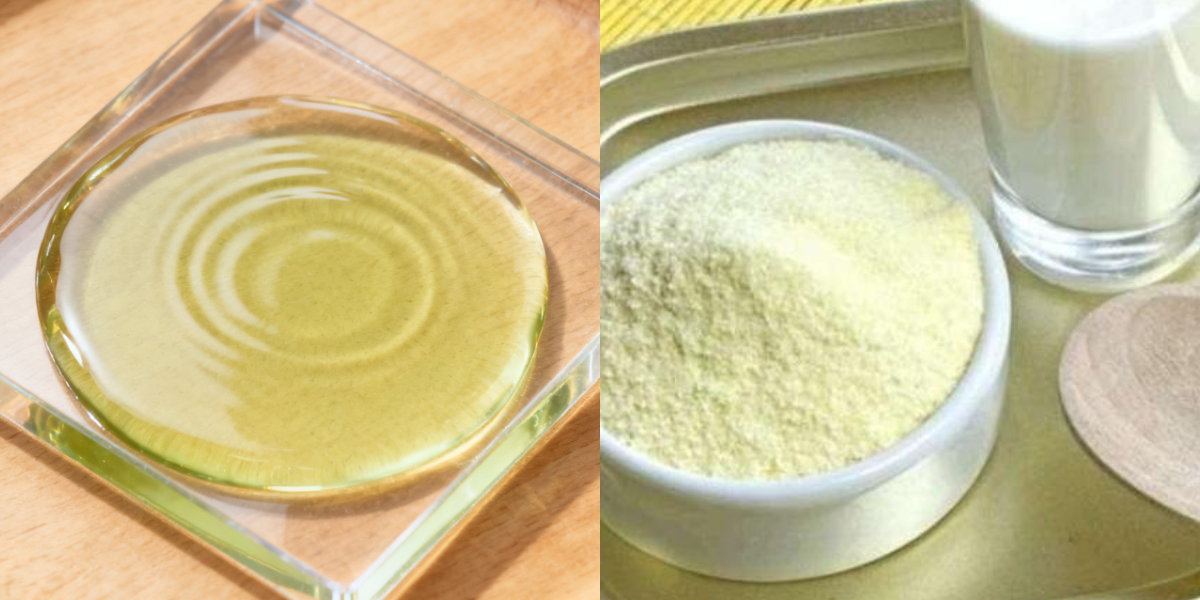

DHA Algal Oil 10kg

Pure and safe source: plant-based source, low risk of contamination

Premium Nutrients: High, free, or low in DHA

Advanced production process: physical extraction process, strong controllability

Excellent product characteristics: low fishy smell and good stability

Suitable for a wide range of people: infants, pregnant and lactating women, adults and the elderly

Product Introduction

DHA algae oil is widely used in the dairy field due to its rich DHA (docosahexaenoic acid, commonly known as "brain gold"), safe source (extracted directly from microalgae to avoid the risk of marine pollutant enrichment), and mild fishy smell, which can accurately match the nutritional needs of different groups such as infants, children, pregnant women, middle-aged and elderly people, etc.

Application of the product

1. Types of dairy products mainly used

DHA algae oil can be flexibly adapted to a variety of dairy product forms, and different product addition scenarios and target groups have their own focus:

Liquid milk: Common products include DHA pure milk and DHA modified milk, mainly for children, office workers, and middle-aged and elderly people. The core challenge in the application of such products is to solve the compatibility problem between DHA algae oil and milk to avoid delamination, so it is often necessary to use appropriate emulsifiers to improve stability. At the same time, liquid milk has a long shelf life, and process optimization is required to ensure that DHA is not destroyed during storage to maintain its nutritional activity.

Fermented dairy products: Typical products include DHA-flavored fermented milk and DHA Greek yogurt, which are suitable for people of all ages, especially favored by pregnant women. The temperature and time during the fermentation process will affect the stability of DHA, so the fermentation parameters need to be strictly controlled. However, the milk protein network in yogurt has an encapsulating effect, which can effectively encapsulate DHA algae oil, reduce the fishy smell to a certain extent, and improve the palatability of the product.

Milk powder: mainly includes infant formula milk powder and DHA adult milk powder, of which infants and young children are the core target population. Since the production of milk powder often involves high-temperature processes such as spray drying, in order to avoid DHA damage by high temperatures, these products mostly use microencapsulated DHA algae oil. Microencapsulation technology can form a protective shell on the outside of DHA algae oil, isolating external factors such as high temperature and oxygen, ensuring the stability and activity of DHA during milk powder production, storage, and preparation.

Cheese/Milk Products: Common products such as DHA cheese sticks and DHA cream, mainly aimed at children's snack scenarios. DHA algae oil can be well integrated with milk fat, but the amount of addition needs to be strictly controlled, if the amount is too high, it may affect the texture of the cheese, such as changing its hardness and ductility, which in turn affects the taste and eating experience of the product.

2. Core application value: nutritional fortification and product differentiation

The core of the application of DHA algae oil in dairy products is to improve the added value of products through the superposition of nutritional functions, and at the same time meet the health needs of specific populations, and the specific value is reflected in the following two aspects:

Addressing DHA Nutritional Needs in Key Populations:

For infants and young children, DHA is an essential nutrient for brain and retinal development, and the "Dietary Guidelines for Chinese Residents (2022)" clearly recommends a daily intake of 100mg DHA for infants and young children aged 0-3 years. DHA algae oil added to infant formula milk powder can provide a convenient and stable nutritional supplement for infants and young children who cannot obtain sufficient amount of DHA through breast milk or complementary foods, and support the development of their nervous system and visual system.

The maternal demand for DHA has increased significantly, which can not only meet their own physiological and metabolic needs, but also be passed on to the fetus/infant through the placenta or breast milk, which is of great significance for fetal brain development and early cognitive development of the baby. DHA fermented milk, DHA milk powder and other products can be used as a supplement to the daily diet of pregnant women to help them easily obtain DHA.

Children are in a critical period of growth and development, and DHA has a positive effect on improving brain function, concentration and vision protection. As middle-aged and elderly people age, their brain and vision function gradually decline, and DHA helps maintain brain cognition and delay vision loss. Related DHA dairy products provide targeted nutritional support for both populations, filling the DHA intake gap in their daily diet.

Help dairy companies achieve product differentiation competition:

In the increasingly competitive dairy market, it is difficult for products that rely solely on basic nutrition to stand out. Dairy products with DHA algae oil have a unique selling point with the "functional" label, which can be clearly different from ordinary dairy products and attract nutritional and health-conscious consumer groups. For example, DHA cheese sticks for the children's market not only meet children's taste needs for snacks, but also provide DHA nutrition, which is favored by parents; DHA formula milk for middle-aged and elderly people focuses on the concept of "nourishing eye protection", which can accurately reach the healthy consumption needs of middle-aged and elderly people and help enterprises gain an advantage in market segments.

3. Key technical points: ensure DHA stability and product palatability

DHA algae oil in dairy applications needs to overcome the two core technical problems of stability and palatability, the specific technical points are as follows:

Microencapsulation technology: This is the core technology to ensure DHA stability. DHA is an unsaturated fatty acid that is easily oxidized and sensitive to light and heat, and is prone to degradation during dairy processing and storage. Microencapsulation technology effectively isolates oxygen, light, and heat by encapsulating DHA algae oil in tiny capsules formed by wall materials (such as maltodextrin, sodium caseinate, gum arabic, etc.), and reduces DHA oxidation and degradation. At the same time, the embedded DHA algae oil particles are finer, which can be better dispersed in dairy products, avoid delamination, and mask their own fishy smell and improve the palatability of the product.

Emulsion system optimization: In liquid dairy products such as liquid milk and fermented milk, DHA algae oil has poor compatibility with the aqueous phase, and is prone to delamination and oil slick. Therefore, it is necessary to optimize the emulsification system, select appropriate emulsifiers (such as monoglycerides, sucrose esters, Tween series, etc.), and reduce the oil-water interface tension through the amphiphilic molecular structure of the emulsifier, so that DHA algae oil can form a stable emulsion and evenly dispersed in dairy products to improve the physical stability of the product.

Process parameter control: Different dairy products have different processing processes, and it is necessary to control the process parameters specifically to protect DHA. For example, in the process of liquid milk sterilization, gentle sterilization methods (such as UHT instantaneous sterilization UHT, which controls the sterilization time and temperature) should be selected to reduce the loss of DHA at high temperatures. In fermented milk production, it is necessary to precisely control the fermentation temperature (usually 37-42°C) and fermentation time to avoid adverse effects of microbial metabolism activities on DHA stability during fermentation. In the process of spray drying of milk powder, it is necessary to control the inlet air temperature, outlet air temperature and atomization pressure to ensure that the microencapsulated DHA is not destroyed during the drying process, and at the same time ensure the solubility and fluidity of the milk powder.

Odor masking technology: Although DHA algae oil has a milder fishy smell than fish oil, it can still have an impact on the taste of dairy products, especially in dairy products with lighter flavors, such as pure milk. In addition to microencapsulation technology, it can also mask the fishy smell by adding flavor substances (such as vanilla flavor, fruit flavor), adjusting the product formula (such as increasing the content of milk protein and sugar), etc. For example, adding fruit flavors such as strawberries and blueberries to DHA-flavored fermented milk can not only enrich the taste of the product, but also effectively mask the fishy smell of DHA algae oil, increasing consumer acceptance.

4. Market trends: demand growth and technological innovation drive development

Upgrading consumer demand drives market size expansion: With the continuous improvement of residents' health awareness, consumers' demand for functional dairy products is growing, especially for specific groups such as infants and pregnant women, and the market demand continues to be strong. According to relevant data, the global DHA market is growing year by year, and dairy products, as an important application carrier of DHA, will also expand their market size. At the same time, consumers' requirements for product quality, safety, and nutritional value are constantly increasing, driving companies to continuously improve the quality of DHA dairy products, such as selecting high-quality DHA algae oil raw materials, optimizing production processes, and strengthening quality control.

Technological innovation helps product upgrades: At the technical level, the production technology and application technology of DHA algae oil continue to innovate. For example, the fermentation technology of DHA algae oil is constantly improving, which can improve the yield and purity of DHA and reduce production costs. Microcapsule embedding technology is developing in the direction of more efficient, stable and safer, such as the development of new wall materials (such as plant-based wall materials and nanoscale wall materials) to further improve the stability and bioavailability of DHA; At the same time, the application of intelligent and automated production equipment and testing technology in dairy production can achieve precise control and quality monitoring of the whole process of DHA dairy production to ensure stable product quality. In addition, companies are constantly exploring the synergy between DHA and other functional ingredients (such as probiotics, lactoferrin, vitamin D, etc.) to develop complex functional dairy products, such as "DHA + probiotic" fermented milk, "DHA + lactoferrin" infant formula milk powder, etc., to achieve the superposition of nutritional functions and meet the diverse health needs of consumers.

Segment Potential: With the intensification of market competition, the DHA dairy market is gradually expanding into segments. In addition to traditional infant formula milk powder, children's cheese sticks and other products, subdivided products for different groups of people are emerging. For example, high-protein DHA whey protein powder for fitness people, low-fat and high-calcium DHA formula milk for middle-aged and elderly people, portable DHA room temperature yogurt for office workers, etc. The development of market segments can not only meet the individual needs of different consumers, but also help enterprises avoid homogeneous competition and find new growth points. At the same time, the regional market is also showing a differentiated development trend, in first- and second-tier cities, consumers have a high awareness and acceptance of DHA dairy products, and the market competition is fierce; In third- and fourth-tier cities and rural markets, with the improvement of residents' income levels and the awakening of health awareness, the market potential of DHA dairy products has gradually been released, becoming an important direction for enterprises to expand the market.

Policies and regulations guide the development of industry norms: Governments of various countries have increasingly strictly supervised food safety and nutrition labeling, and the introduction of relevant policies and regulations has provided a guarantee for the standardized development of the DHA dairy industry. For example, the Chinese national standard "GB 14880-2012 Standard for the Use of Food Nutritional Fortifiers" clearly stipulates the scope and maximum amount of DHA in dairy products such as infant formula, infant and toddler formula, children's formula, and adult formula, ensuring the safety and compliance of DHA dairy products. At the same time, the policy encourages enterprises to carry out functional food research and development and innovation, supports the production and promotion of high-quality functional dairy products, and creates a good policy environment for the development of the DHA dairy industry.

Packaging & Shipping

We usually use bulk cargo, tank trucks, container transportation. We will arrange the most cost-effective shipping method according to the quantity of products. All products will be re-inspected before shipping. We guarantee that all products are strictly inspected and in good condition before shipment, and we strive for 100% customer satisfaction in every sale completed. The packaging is standard export packing, or customized packaging according to your requirements, professional cargo transportation agent.

Sales Service

Pre-sales service: Provide application solution support for customers before purchasing to help customers understand products and applications.

Product consultation: Answer customers' questions about product functions, features, prices, usage and other questions in detail.

Demand analysis: Recommend suitable product solutions based on the customer's industry, scenarios, pain points, etc.

Information provision: such as product manuals, case studies, quotations, etc., to assist customers in decision-making.

In-sale service: Provide convenience and support to customers during the transaction process to ensure smooth transactions.

Order processing: Quickly and accurately enter order information to confirm product specifications, quantities, delivery dates, etc.

Payment guidance: Assist customers in completing the payment process and answer questions about payment methods and invoicing.

Progress communication: Timely feedback to customers on order processing progress, logistics information, etc., so that customers can rest assured.

After-Sales Service: Ongoing support provided to customers after the transaction is completed, enhancing customer satisfaction and loyalty.

Return and exchange processing: Handle the return and exchange procedures for customers in accordance with regulations to reduce customer worries.

Customer return visits: understand customer usage, collect feedback, and provide basis for product improvement and service optimization.

Company Introduction

Founded in 1997, Bowlingbao Biotechnology Co., Ltd. has always focused on modern bioengineering technologies such as enzyme engineering and fermentation engineering, engaged in the research and development, manufacturing and program services of functional sugars, and is a national key high-tech enterprise led by bioengineering, a national key leading enterprise in agricultural industrialization, a national manufacturing single champion enterprise, a national high-tech zone, and a national high-tech biological industry base core and backbone enterprise. In 2009, the company was listed on the Shenzhen Stock Exchange, becoming the first A-share listed company in China with the stock code: 002286.

The pioneer and leader of China's functional sugar industry, adheres to the restoration of traditional medical and nursing wisdom with modern biotechnology, serves the big health industry, and has the ability to manufacture and serve all categories of functional sugar. A leading global provider of functional health solutions.

Product Catalog

Starch sugar: solid corn syrup, waxy corn starch, maltodextrin, malto-oligosaccharides, fructose syrup, maltose

Dietary fiber: polydextrose, resistant dextrin, water-soluble corn fiber

Prebiotics: isomalto-oligosaccharides, fructooligosaccharides, galacto-oligosaccharides, breast milk oligosaccharides, isomerized lactose

Sugar alcohols and new sugar sources: allulose, erythritol, crystalline fructose, compound sweeteners, trehalose

Modified starch: special for yogurt, special for sauce, special for baking fillings, special special for baked products, special special for flour products, special special for meat products

Functional lipids: DHA algae powder, DHA algae oil, DHA algae oil crude oil